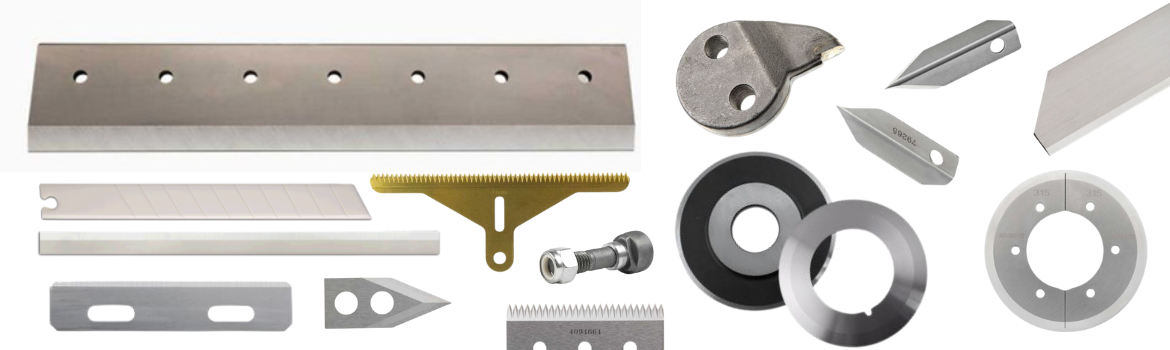

Industrial Knife and Blade Material Selection Basics

The purchase of industrial knives and blades is typically made based on price. End-users know what knife or blade is required for the machine, they look up the correct item number, compare prices and then buy the product that has the best competitive price. Many decision makers are unaware that changing the material of a knife can influence the performance of the blade including better wear resistance, improved cutting performance, and superior slit quality. As we have mentioned in previous blog posts, metallurgy matters when considering the right material for your cutting application.

Looks Can Be Deceiving

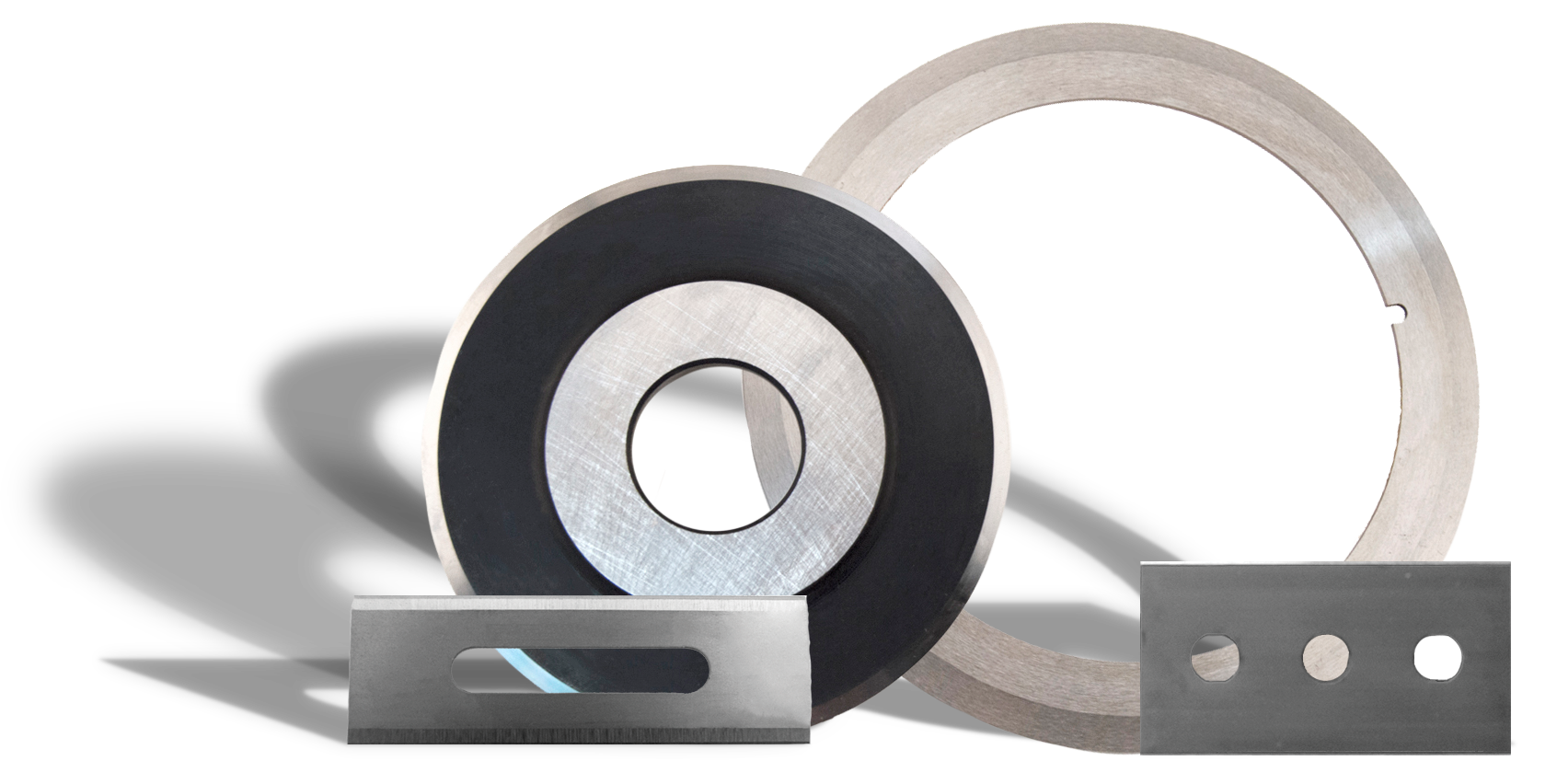

Just because two knives look alike, doesn't mean they're the same. They could be made of different materials. The only way to accurately differentiate between blades that look alike on the surface is to know their material makeup and Rockwell hardness.

Steel is made from iron ore that has had the impurities burned out of it through a process called smelting. The most basic steel manufactured from the smelting process is AISI 1018 material, which is primarily used in the body of automobiles, basic jigs, and fixtures.

Each type of material is assigned an AISI number that consists of four digits. AISI stands for American Iron and Steel Institute. The AISI categorizes different types of steel and keeps track of where any particular steel fits into the family of steels. To read an AISI number, we look at the first two numbers of an AISI number show the alloy content. The second two numbers designate the carbon content.

Carbon is present in any kind of steel and provides hardenability, which means that the steel can be strengthened through the use of heat treating. All knife steels require hardening after machining to bring out the optimal wear characteristics of the material. The process happens in a furnace that heats the steel up to its hardening temperature, which depending on the grade of the steel can be anywhere from 1,500 to 2,000 degrees Fahrenheit. When discussing different levels of knife hardness, the Rockwell C scale is commonly used. The chart* below provides the Rockwell C scale for each commonly used steel.

Rockwell Hardness Testing Scale

| Scale | Testing Application |

|---|---|

| A | Extremely hard materials such as Tungsten Carbide and thin, hard sheets |

| B | Materials of medium hardness – low and medium carbon steels in the annealed condition |

| C | Materials harder than Rockwell B-100 |

| D | For times when a somewhat lighter load is desired than on C scale, as on case hardened pieces |

| E | For very soft materials such as bearing metals |

*Source: Robert E. Green, Machinery's Handbook, 24 Edition. Industrial Press, NY, NY

Formulating Steel Based on Use

Steel engineers develop various formulations of steel based on its intended use. Alloys are included in steel formulas to give steel different physical characteristics based on its planned application. Some of the more common alloying elements include:

| Alloy | Characteristics |

|---|---|

| Carbon | The principal hardening agent of steel |

| Manganese | Contributes to strength and hardness |

| Phosphorus | Increases machinability and resistance to corrosion |

| Molybdenum | Corrosion resistance and reduces brittleness at high hardness |

| Chromium | Increases corrosion resistance, wear resistance, and high-temperature strength |

| Nickel | Medium hardness, high ductility, corrosion resistance |

Three Basic Categories of Steel

| Plain Carbon Steel Grades | Alloy Grade Material | Tool Steels |

|---|---|---|

| Contain no alloying elements. Will harden but will not exhibit improved alloying characteristics. Examples: 1050, 1075, 1080 |

Attain a hardness and display some improved performance due to additional alloys. Examples: 52100, 4142, 4150 |

Attain a hardness and display improved wear, toughness, and strength. Examples: 0-1, D-2, M-2 |

Carbide, Ceramic, and Powdered Metal

When we think of industrial knives and blades, we think of hard steel. However, carbide and powdered metal are also important industrial blade materials.

Carbide is a composition of tungsten and a binder material like cobalt. These materials are mixed and sintered at 2,500–2,900°F. Carbide is extremely hard and is tested on the Rockwell A scale.

Carbide Rules of Thumb

- The finer the grain size, the higher the hardness

- The lower the cobalt content, the higher the hardness

- The higher the hardness, the greater the abrasive wear resistance

- The lower the cobalt content, the lower the strength

- The finer the grain size, the lower the strength

Test run comparisons show carbide can offer up to 10x more production life compared to 52100 steel.

Ceramic

Used in aerospace and converting, ceramic knives maintain hardness at high temperatures but are brittle. Their brittleness can cause chipping and shorter run times.

Powdered Metals

Powder metallurgy steel differs from traditional methods. Instead of melting and slow cooling, the metal is atomized into powder, screened, poured into containers, and solidified using particle metallurgy. The result is improved machinability, grindability, and uniform performance.

Conclusion

No two cutting applications are the same. High quality manufacturers like American Cutting Edge have experts available to analyze your needs and recommend the right material for your application—saving you money without compromising quality.

Reach out to the experts at American Cutting Edge today to discuss your requirements and put our experience and knowledge to work for you.