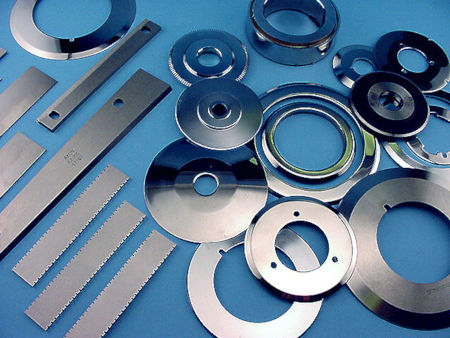

General Machine Knife Information

American Cutting Edge understands industrial machine knives and blades of all shapes and sizes from stump teeth grinders, large granulator knives, ceramic blades, wood chipper blades and steel processing knives to smaller packaging tape knives, sheer slitters, hook blades, tungsten carbide blades and fiberglass chopping blades – just to name a few. With over 60 years of industrial knife and blade manufacturing experience, we’ve worked in many industries over the years. We’ve developed a level of experience you just can’t get anywhere else.Our experience provides customers with a unique perspective and understanding of industrial blades – no matter what the size. There’s simply no voice like the voice of experience.

Grades of Steel

All grades of steel are broadly categorized into four groups, based on chemical composition:

- Carbon Steels - steel with carbon content up to 2.1% by weight

- Powdered Metals - completely uniform in chemical composition as each powder particle solidifies from a homogenous pre-alloyed bath producing a 100% dense steel with no residual porosity providing higher wear resistance and improved toughness

- Stainless Steels - iron-based alloys that contain a minimum of approximately 11% chromium, a composition that prevents the iron from rusting.

- Tool Steels - a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures.

According to the World Steel Association, there are currently 3,500 different grades of steel. Each grade is marked by a unique combination of physical, chemical, and environmental properties. Selecting the ideal grade for a specific cutting application begins with understanding the various options available. Each grade of steel is defined by its relationship to wear resistance and toughness based on working hardness. Choosing the ideal grade and hardness of steel depends on the application requirements of the job at hand.

It’s not just about the raw materials or the edge preparation of the knife. You need to work with a supplier who asks the right questions. Here are just a few of the many topics your industrial knife and blade manufacturer should be discussing.

- Your machine – What is it? Make, model, and knife configuration? What’s the maintenance schedule been like?

- Your material – What are you cutting? Is it virgin material, abrasive material, post-industrial material? What are the challenges and special considerations of this material?

- Your industrial knives and blades – How often are they changed? Where do they come from? How’s the cut quality? Has it changed? Do you precision sharpen your knives and blades?

- Failure and performance – Mode of failure, how long did the knife last, what changed since the problem began?

- Sample knife or blade – ACE always asks for a sample that exhibits the current mode of failure so we can fully understand exactly what’s happening and make the right recommendation to correct the problem.

When you’ve got a cutting challenge to solve, you want to make sure that you have a team with the right experience on your side to ensure sure you’re making the right decisions. As a leader in OEM compatible knife, machine knife and cutter blade manufacturing, Contact the ACE experts today for more information or to request a quote.