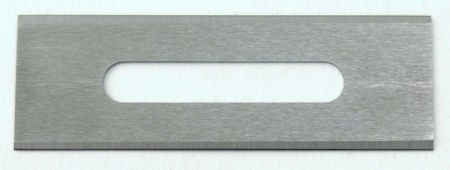

Tungsten Carbide Blades

One of the proudest moments in our company history is that we created the first successful tungsten carbide blades for use as razor blades. These blades have been used for many years in larger knives, but the geometries of thin blades made their use more difficult. While tungsten carbide is much more wear-resistant, it is also more susceptible to breakage and thus the older grades of material would not work for these special blades. We finally found the correct carbide grade for tungsten carbide blades and since then have almost “owned the market” for these special blades.

High-Performance Tungsten Blades

Tungsten Carbide blades need to be ground on special machines that use diamond wheels to remove the material. We experimented with many different wheels and are now experts at creating the correct finish on every surface of the blade. We now make our carbide cutting edges to a 2 to 4 RMS finish and can even do better than that if it is required. With our combination of material selection, special grinding machines, EDM machines, and blade knowledge, we are the best company in the world to make specialty blades!

Send us your Knives’ Requirements

We carry a wide variety of blades. However, what may be a special project to you might not be for us. Send us your requirements and we can find out. These tungsten carbide blades are used for cutting rubber, packaging, plastics, fiber, film, foil, mat board, capsules as well as other products. With our motto of “Easy to do business with” we make sure we can ship all blades the same day we get the order.

Making Custom Blades Since 1965

We have been making custom blades since 1965. When you need a company that can assist you from design through production, we can help. We have the expertise to assist you and look forward to your inquiry.

Contact American Cutting Edge today and let us help you manufacture a custom tungsten carbide blade designed to your specifications. We also carry an extensive inventory of standard carbide razors