Top 3 Things to Consider When Choosing a Food Knife Vendor

There's much more to your replacement food processing blades than the price you pay for them. Many food processing companies don't stop to think about all the factors that go into their cutting and processing application, instead of focusing purely on choosing a partner based on the lowest cost provider. Some companies don't realize they have a choice when it comes to replacing their knives and blades.

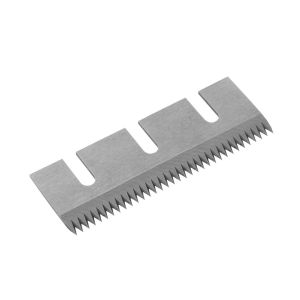

Food processing equipment requires blades with tight tolerances, which means that quality matters more than ever when choosing your supplier. There's no question that the quality of the blade or knife makes all the difference in any cutting operation. It's the ability to maintain a sharp cutting edge and blade stability that can make or break a production facility whether they're processing meat, vegetables, packaging dry goods, or fresh food.

Blade Material – You Have Options

Of particular importance is blade material when it comes to food processing. It's critical to make certain that  food-grade materials, coatings, and oil are used. Blades must be stable to ensure that no chipping, breakage, or blade artifact is getting into the food being processed. Blade quality is one of the best ways to mitigate risk and avoid costly recalls and reputational damage.

food-grade materials, coatings, and oil are used. Blades must be stable to ensure that no chipping, breakage, or blade artifact is getting into the food being processed. Blade quality is one of the best ways to mitigate risk and avoid costly recalls and reputational damage.

For example, meat processing knives such as skinner blades are readily available in the industry-standard material, 440C. But there are other material options. With decades of experience making food processing knives, American Cutting Edge has been instrumental in the advancement of blade materials that help our valued customers achieve a consistent and profitable operation without sacrificing their budget. One of those advancements is the addition of carbon to replacement skinning machine blades.

Industrial Knife Engineering Experience

An organization with an in-house engineering team that truly understands cutting applications can review blade failures, troubleshoot the production line, evaluate materials and get to the root of the  problem quickly. Sometimes there's an opportunity to increase efficiency and reduce wear by switching the material from carbon to stainless steel depending on what's being processed.

problem quickly. Sometimes there's an opportunity to increase efficiency and reduce wear by switching the material from carbon to stainless steel depending on what's being processed.

There have been times when our team has reviewed video footage and times when on-site visits have been more appropriate. Other times, we've looked over drawings and even the failed blade itself. It depends on the scope of the problem. For some of our customers' more complicated challenges, we've even pulled engineering in to make modifications to existing blades. Regardless of proximity to the customer, our goal remains the same and that's to work in partnership with our customers to make cutting more effortless and more profitable for them.

When you work with a broad range of industries, you must have an engineering department that can apply their knowledge and understanding from one type of customer to the next without skipping a beat. As an industrial knife supplier, we're often called upon by our customers to help them to improve a process or solve a problem that has slowed down or even stopped their cutting operation. We must understand not only the industrial knives and blades we produce but also the material and coating options, the cutting application in use, how the materials will respond in the knife manufacturing process, and how they will perform when in use in terms of toughness and wear resistance,” explains American Cutting Edge Director of Engineering, Mike Hammel.

Inventory and Supply Chain

Not all suppliers have a supply chain that's able to keep their customers stocked with the right blades when the need arises or when priorities shift in their operation.

Working with a supplier that has a global supply chain and multiple sources for the materials you need is critical. Organizations with solid relationships around the globe are less likely to be impacted in the event of an unforeseen economic crisis, natural disaster, or global event like the coronavirus pandemic. Manufacturers without a rock-solid supply chain can struggle when ports close and shipments are stuck on the docks or on the water waiting to come into port.

There are many things that companies can do to drive a successful supply chain initiative including huge investments in technology but the greatest opportunity for success comes from a focus on relationships.

Mismanagement of supply chain relationships can have a devastating effect from suppliers clear through to customers. Strong relationships benefit the organization, the supply chain, and ultimately the end customer.

Effective supply chain relationships carry the benefits of:

- Creating a collaborative and cooperative environment

- Fostering innovation

- Better compliance with rules and regulations

- Greater transparency and access to information

American Cutting Edge has a solution for every operational challenge whether you're looking for cost savings, increased yield, or corrosion resistance. If the answer to your problem isn't on our shelf, we can create custom solutions to help you get the results you need.

Contact the food processing specialists at American Cutting Edge to learn more about how we can support your needs.