ACE Meat Skinners vs. the OEM

Purchasing the right replacement knives and blades for your OEM equipment should be effortless. We've spoken before about how industrial knife manufacturers like ACE can help customers optimize cutting performance. Skilled industrial knife manufacturers can be an excellent resource for supplying the replacement industrial machine knives, razor blades, and wear parts you need.

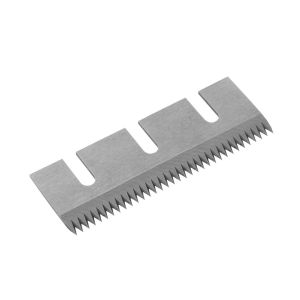

Today's blog focuses on the meat skinner blades made by ACE vs. those manufactured by the OEM. American Cutting Edge manufactures meat skinning blades that are compatible with the largest OEMs in the business including Maja® and Townsend®.

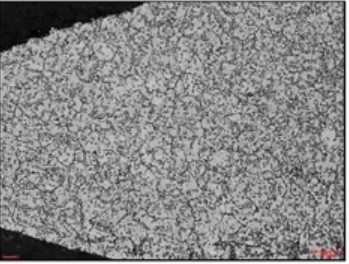

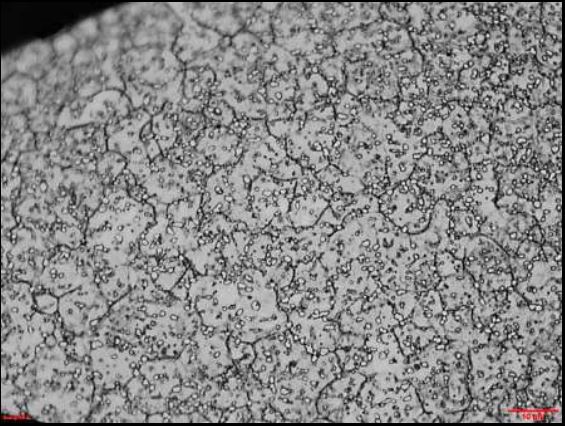

Independent laboratory testing of ACE brand skinner knives compared to a major OEM blade concluded that the microstructure of the ACE brand blade and the OEM blade are structurally and chemically the same. Both exhibited a fine grain size with a significant quantity of chromium carbides along the grain boundaries that reduce the potential of cracking and chipping of the knife edge.

Without exception, meat derinding and membrane skinning knives have to be razor sharp and rust resistant. Designed for rapid, accurate processing of beef, lamb, fish, and poultry, accuracy, consistency, and speed are incredibly important features of meat skinner blades.

The stainless steel composition minimizes nicks and cuts for longer skinning sessions, and their heavy-duty, drag-free construction maximizes operator productivity.

Both close-up images featured in this blog show microstructures with more refined grain and significant chromium carbides along the grain boundaries. The top close-up image is the American Cutting Edge blade and the second is the OEM version.

There is no guesswork involved when it comes to making OEM-compatible knives and blades at American Cutting Edge. ACE has the technical capabilities to make its knives and blades to the exact specifications of the OEM print. Keeping the tolerances of the OEM knife or blade is critical for both knife fit and blade performance. The slightest deviations can cause an increase in downtime and maintenance, which translates into unnecessary expense and waste for your cutting operation.

Partner directly with the source of your industrial knives, blades, and replacement parts. Get to the root of any manufacturing or stocking issues with a single phone call. Industrial knife manufacturers that have a deep understanding of metallurgy and cutting applications can evaluate your entire cutting operation to determine where and why failures occur.

Industrial knife and blade manufacturers understand your operation from the beginning to the end across the multiple processes in your production line. Across every step from the first cut to the last, your knife supplier's engineering and account team should understand where opportunities for optimization exist and how you can get more from your production environment via materials, geometry adjustments, and technical enhancements others might miss.

The right industrial knife supplier will work with end users, engineers, and maintenance managers to truly understand your application and process. Work with a team that has knowledge beyond knives. Partner with an organization that knows cutting and can help you recognize optimization opportunities that others might miss.

Contact the experts at American Cutting Edge to engage the expertise of our dedicated food processing team.