Die Resurfacing and Grinding in Small Underwater Pelletizing Operations

Underwater pelletizers know that machine uptime is paramount. When pelletizers are down, production suffers. Minimizing blade and die change-out ensures that maximum productivity is achieved and increases the lifetime of the pelletizer.

In an effort to reduce pelletizer downtime, some operators push dies past their limits. As a result, pellets become inconsistent and may require re-processing and pelletizer blades must be changed more often. If pellets are not re-processed, customers may be shipped inferior product resulting in customer dissatisfaction and eventual loss of business.

Forgoing maintenance also negatively impacts the pelletizer machine and leads to breakdowns. Significant pelletizer breakdowns require failure analysis and extended repair times. This increases long-term shutdowns and contributes to decreased production and loss of profits. In extreme cases, pelletizer machines can be ruined by a lack of maintenance and can cause unsafe working conditions.

Planned die maintenance reduces these failures and allows underwater pelletizers to operate with confidence, ensuring the safety of their team, the consistency of their product, and the longevity of their pelletizer.

"Every dollar spent on preventive maintenance will save you five dollars on other expenses." - Mintek

Recognizing Die Breakdown

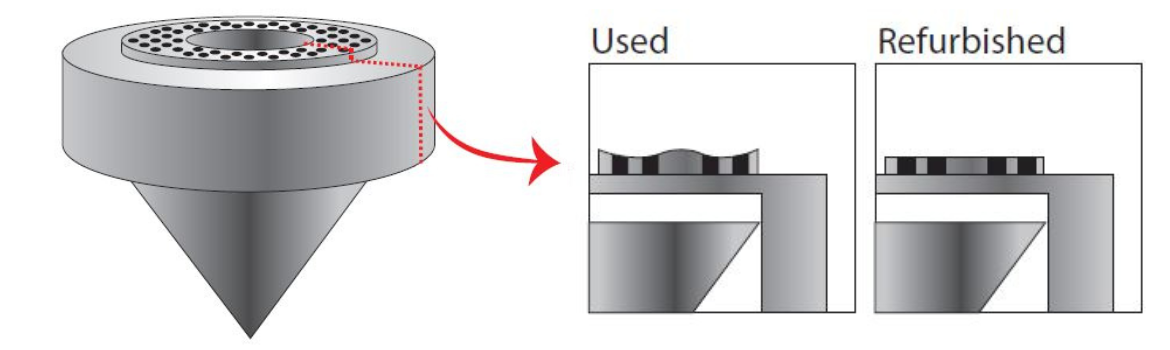

The simplest way to recognize the need for die maintenance is through visual inspection. Check for grooves in the die, especially those that appear to be deeper in some areas. Unusual wear patterns on the die will cause inconsistencies in pellets and contribute to premature blade wear.

In addition to inspecting the die, operators should routinely examine the pellets as they come out of the machine to check for evidence of increased finds and daisy chains. Pellets should be spherical and identical; any deviations indicate a potential maintenance need. Excessive or inconsistent wear of the blades can also indicate the need for die maintenance.

Establish maintenance and inspection intervals based on the amount of product that is processed. When establishing new maintenance and inspection procedures, check the die, blades, and pellets frequently and record observations and the amount of product processed. Use this information to create a consistent inspection and maintenance procedure that supports the needs of the operation.

"A company can save between 12-18 percent using preventive maintenance over reactive maintenance.“ - Mintek

Performing Die Maintenance Saves Money

Periodic die maintenance not only decreases downtime and increases product quality, operator safety, and blade life, it also reduces maintenance costs. As one of the most costly, maintenance actions, die replacement is often avoided as long as possible. Die resurfacing and grinding allows underwater pelletizers to extend the life of dies and can be performed at a fraction of the cost of die replacement, saving underwater pelletizers thousands.

When performed by a precision die grinder and resurfacer, dies undergo 100 percent inspection to ensure there are no defects that may compromise the integrity of die after grinding. During this inspection, precision grinders determine the amount of material that will be removed. The goal is always to remove as little of the stock material as possible to maintain the longest life. Generally, die resurfacing requires the removal of only a few thousandths of an inch.

During the grinding process, the die is flooded with specialized coolant to eliminate the risk of overheating the material and inadvertently altering the chemical makeup of the die. Dies manufactured of tool steel require a different coolant than those containing carbide. Throughout the resurfacing process, the die undergoes periodic inspection to ensure the integrity and tolerances of the die.

Underwater pelletizers should maintain a minimum of three dies, one in operation, one in maintenance, and one on the shelf to utilize in case of failure. Die maintenance can often be completed in as little as 7 to 10 days, allowing underwater pelletizers to plan ahead and ensure seamless production.

Minimize blade wear and change outs, increase productivity and pellet quality, decrease operational costs, and ensure a safe working environment by performing routine underwater pelletizer die maintenance.