Five Benefits of Vendor Consolidation in Manufacturing

There’s a lot to be said for simplification whether you’re thinking about clearing the clutter in your office, streamlining your schedules, or committing to meal planning at home. The idea of simplifying boils down to making life easier. If you’ve ever consolidated your bills or cleared out items by donating to charity, you’re familiar with how effortless things can be when they are simpler.

This concept extends to manufacturing operations of all kinds when organizations look at their vendor and procurement policies.

“Simplicity is the prerequisite for reliability.” – Edsger Dijkstra

What is Vendor Consolidation?

Vendor consolidation is a cost-reduction strategy that involves reducing the number of suppliers for your business to a few or in some cases even one. While it might seem that reducing the number of sources for the things you need might make the organization more unstable in terms of competitive bidding or having a supplier fold, the opposite is true.

Today we are reviewing the top five benefits of vendor consolidation. At the end of this post, I’ll provide an example of the type of savings that might be achieved through the vendor consolidation process.

“Simplicity is the ultimate sophistication.” – Jeff Rich

Vendor Consolidation – Five Benefits

While there are many benefits to reducing the number of vendors involved in your production line, I’m going to focus on the top five that apply to most of our ACE customers.

1. Reduced Purchasing Costs – As the supplier base reduces, purchasing power increases due to the ability to allocate more resources to fewer suppliers.

2. Reduced Process Costs – As purchasing deals with fewer vendors, transactional costs decline. This can be a significant savings when one considers the cost of setting up and maintaining suppliers in internal systems.

3. Reduced Risk – Reliance on fewer suppliers significantly reduces risk. The shift moves to focusing on securing all applicable risks throughout the supply chain.

4. Improved Supplier Relationships – Fewer suppliers provides an opportunity to build better relationships with core suppliers. Not only do customers benefit from cost improvements but also on building more solid partnerships. Vendor consolidation produces a natural focus on quality, efficiency, and performance.

5. Better Overall Solutions – Businesses that work with fewer suppliers are able to work with vendors who are able to look at their business in totality rather than those that offer spot solutions, which might be less comprehensive in nature. There are major benefits when a vendor becomes a partner like ACE that can take a deep dive into providing options for operational efficiency.

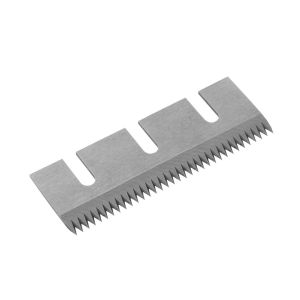

ACE Senior Packaging Product Manager, Heather Vreeland states, “Because ACE understands industrial blades across multiple production and manufacturing lines, we’re able to provide customers with solutions with much greater depth and breadth. One of the many examples of this is when we look at how our food processing customers overlap with our packaging knife expertise.”

Vreeland continues, “When we partner with customers and provide the majority of their knives and blades, we’re in a much better position with our supply chain. An improvement in our supply chain position can translate to up to a 30% reduction in cost to our customers. Through the use of warehouse and blanket purchase agreements, ACE is able to partner with customers to get the best pricing available for the quantity of blades they project for their food and packaging line. ACE can even keep those items in inventory at our warehouse, eliminating the risk of stock outs and ship those blades so they arrive at exactly the right time.”

According to ACE Chief Operating Officer, Gregory Billhardt, finding the right food processing and cutting tool partner has a lot more to it than just getting a good price. “We’ve found over the course of our 55-year history that along with competitive pricing, customers benefit greatly from the industrial knife experience that we bring to the table. Our level of understanding when it comes to materials, coatings, and cutting applications provides us with the unique opportunity to truly consult with customers to ensure the blades they’re using provide the best output for their lines.”

According to Billhardt, “Unlike larger ‘do-it-all’ companies, ACE is able to ask the right questions and help our customers find solutions that are not only price-competitive but reduce blade change outs, save maintenance costs, and help make their operations more profitable overall. Sometimes this process involves making modifications to existing designs, adding special food-safe coatings, or even designing a custom solution. Our goal is to provide solutions to our customers that help them run a more efficient operation, not just sell a knife or blade.”

Contact the food processing and packaging cutting experts today to learn how we can help your organization operate more efficiently and cost-effectively.