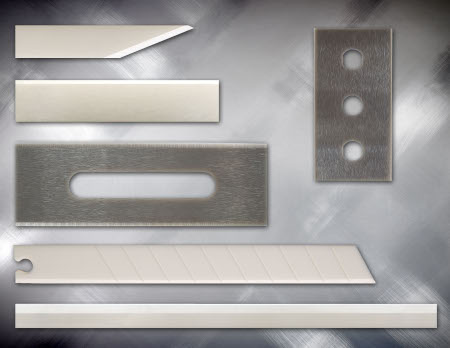

American Cutting Edge has the largest inventory in North America of slitting blades. We stock all types of injector blades, slotted blades, and 43mm 3-hole slitter blades. Due to the diversity of the material being slit, we offer all these blades in a wide range of thicknesses, materials, edge geometries and coatings. Our extensive inventory enables us to provide same day shipping for all standard items.

Razor slitting is often used when narrow strips are required or when the application has need for there to be only a small bit of material displacement as the cut product passes by the blade. Regardless of the slitting application, we know the application and we can help improve yield and reduce downtime! We offer these blades in not only carbon, stainless steel, and tungsten carbide but also with ceramic or titanium nitride coating. These tungsten carbide blades and those that are coated will last much, much longer. We introduced the first successful solid tungsten carbide blades back in 1972, so we know a thing or two about their performance!

We stock many coated blades, using TIN, TIC, and Boron Carbide (ceramic coating). TIN is much less costly but offers a little longer life while TIC lasts much longer but the heat required to apply it makes it not as good for thinner blades. Often ceramic is the best choice, as the blades will not warp during coating and it offers a very long life. All these coatings work best in certain applications and we request that you ask your ACE representative for which blade would work best for you.

Our focus is to make consistent quality blades where the 10,000th piece is as good as the first piece. You don’t just need one good blade; you may need thousands of good blades! We can modify the edge geometry to make the blade cut best for your application. If you need blades with a single bevel, a double bevel or even a compound double bevel, we can do it.